Products

- Capacitor Networks, Arrays(2073)

- Aluminum Electrolytic Capacitors(119232)

- Tantalum Capacitors(106098)

- Ceramic Capacitors(802073)

- Electric Double Layer Capacitors (EDLC), Supercapacitors(2508)

- Film Capacitors(165215)

- Accessories(256)

- Mica and PTFE Capacitors(9477)

- Trimmers, Variable Capacitors(1755)

- Thin Film Capacitors(3401)

- LED Character and Numeric(4347)

- Display Bezels, Lenses(87)

- LED Emitters - Infrared, UV, Visible(3590)

- Laser Diodes, Modules(800)

- LED Dot Matrix and Cluster(634)

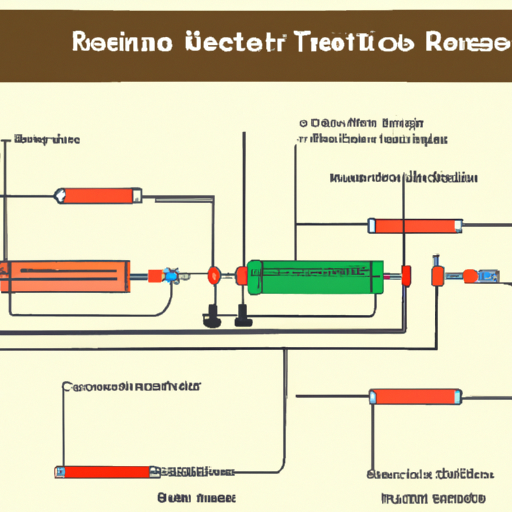

- Ballasts, Inverters(204)

- Optoelectronics Accessories(6346)

- LCD, OLED Character and Numeric(1966)

- Spacers, Standoffs(2700)

- Incandescent, Neon Lamps(1242)