The Role of Starting Capacitor Products in Practical Applications

I. Introduction

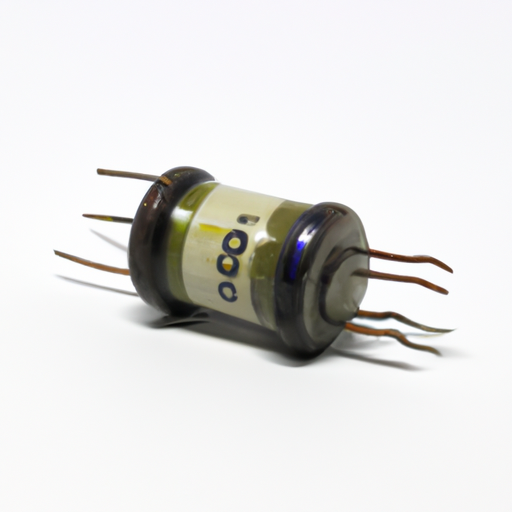

Starting capacitors are essential components in various electrical systems, particularly in applications involving electric motors. These capacitors play a crucial role in providing the necessary boost to initiate the operation of motors, ensuring they start efficiently and effectively. In this blog post, we will explore the definition of starting capacitors, their importance in electrical systems, and their practical applications across different industries.

II. Understanding Starting Capacitors

A. What is a Starting Capacitor?

A starting capacitor is a type of capacitor used to provide an initial surge of energy to an electric motor, particularly single-phase induction motors. When the motor is powered on, the starting capacitor temporarily increases the current flow, creating a phase shift in the motor's windings. This phase shift generates a rotating magnetic field, which is essential for starting the motor.

1. Definition and Function

Starting capacitors are designed to store electrical energy and release it quickly to provide the necessary torque to start the motor. They are typically rated for short-term use, as they are only needed during the initial startup phase. Once the motor reaches a certain speed, the starting capacitor is disconnected from the circuit, often by a centrifugal switch or an electronic relay.

2. Types of Starting Capacitors

There are several types of starting capacitors, including:

Electrolytic Capacitors: These are commonly used in applications requiring high capacitance values. They are polarized and must be connected correctly to avoid damage.

Non-Polarized Capacitors: These capacitors can be used in AC applications and are often found in smaller motors and appliances.

Motor Run Capacitors: While not strictly starting capacitors, these are used in conjunction with starting capacitors to improve motor efficiency during operation.

B. How Starting Capacitors Work

1. Electrical Principles

Starting capacitors operate based on the principles of capacitance and reactance. When voltage is applied, the capacitor charges and stores energy. The stored energy is then released quickly, providing a burst of current to the motor windings. This surge of current creates a magnetic field that helps the motor overcome inertia and start turning.

2. Role in Induction Motors

In single-phase induction motors, starting capacitors are vital for creating the necessary phase shift between the current in the main winding and the auxiliary winding. This phase shift is crucial for generating the rotating magnetic field that allows the motor to start. Without a starting capacitor, single-phase motors would struggle to start, leading to inefficiency and potential damage.

III. Applications of Starting Capacitors

A. HVAC Systems

Starting capacitors are widely used in HVAC systems, particularly in air conditioning units. They help the compressor motor start efficiently, ensuring that the system operates smoothly. The use of starting capacitors in HVAC systems can significantly impact energy efficiency, reducing the overall power consumption and operational costs.

B. Electric Motors

Starting capacitors are essential in various electric motors, especially single-phase induction motors. These motors are commonly found in household appliances, industrial machinery, and commercial equipment. The use of starting capacitors allows these motors to start quickly and efficiently, improving overall performance and reliability.

C. Refrigeration Systems

In refrigeration systems, starting capacitors play a critical role in the operation of compressors. Compressors require a significant amount of torque to start, and starting capacitors provide the necessary boost. By enhancing the performance and reliability of refrigeration systems, starting capacitors contribute to maintaining optimal temperatures and energy efficiency.

D. Power Tools and Equipment

Starting capacitors are also found in handheld power tools and equipment. Tools such as drills, saws, and lawnmowers often utilize starting capacitors to ensure smooth operation. The benefits of using starting capacitors in power tools include improved performance, reduced wear and tear, and increased longevity.

IV. Benefits of Using Starting Capacitors

A. Improved Starting Torque

One of the primary benefits of using starting capacitors is the improved starting torque they provide. This increased torque allows motors to overcome initial resistance and start quickly, reducing the risk of stalling or overheating.

B. Enhanced Motor Efficiency

Starting capacitors contribute to enhanced motor efficiency by ensuring that motors start smoothly and operate at optimal performance levels. This efficiency translates to lower energy consumption and reduced operational costs.

C. Reduced Electrical Noise

Starting capacitors help reduce electrical noise generated during motor startup. This reduction in noise can lead to a more pleasant working environment, particularly in residential and commercial settings.

D. Protection Against Overheating

By providing the necessary starting torque, starting capacitors help prevent motors from overheating during startup. This protection is crucial for extending the lifespan of the motor and reducing maintenance costs.

E. Cost-Effectiveness in Long-Term Use

While starting capacitors may represent an initial investment, their benefits in terms of improved efficiency, reduced wear and tear, and enhanced performance make them a cost-effective solution in the long run.

V. Challenges and Considerations

A. Selection Criteria for Starting Capacitors

When selecting starting capacitors, several criteria must be considered:

1. Voltage Ratings

It is essential to choose a starting capacitor with the appropriate voltage rating for the specific application. Using a capacitor with a lower voltage rating than required can lead to failure and potential damage to the motor.

2. Capacitance Values

The capacitance value of the starting capacitor must also be matched to the motor's requirements. An incorrect capacitance value can result in inadequate starting torque or excessive current draw.

B. Common Issues and Troubleshooting

1. Signs of Failure

Common signs of starting capacitor failure include difficulty starting the motor, unusual noises, and overheating. Regular maintenance and inspection can help identify potential issues before they lead to complete failure.

2. Replacement and Maintenance

Replacing a faulty starting capacitor is crucial for maintaining motor performance. It is essential to follow manufacturer guidelines for replacement and ensure that the new capacitor is compatible with the motor.

VI. Future Trends and Innovations

A. Advancements in Capacitor Technology

As technology continues to evolve, advancements in capacitor technology are expected to enhance the performance and efficiency of starting capacitors. Innovations may include improved materials, higher capacitance values, and better thermal management.

B. Integration with Smart Systems

The integration of starting capacitors with smart systems and IoT technology is another trend on the horizon. Smart systems can monitor motor performance and optimize the use of starting capacitors, leading to improved energy efficiency and reduced operational costs.

C. Environmental Considerations and Sustainability

As industries move towards more sustainable practices, the development of environmentally friendly starting capacitors will become increasingly important. Manufacturers are likely to focus on creating capacitors that minimize environmental impact while maintaining performance.

VII. Conclusion

In conclusion, starting capacitors play a vital role in various practical applications, particularly in electric motors, HVAC systems, refrigeration, and power tools. Their ability to provide the necessary starting torque, enhance motor efficiency, and protect against overheating makes them indispensable components in modern electrical systems. As technology continues to advance, the future of starting capacitors looks promising, with innovations that will further improve their performance and sustainability. Understanding the importance of starting capacitors and their applications can lead to better maintenance practices and more efficient use of electrical systems. We encourage further research and exploration into this essential component of electrical engineering.

The Role of Starting Capacitor Products in Practical Applications

I. Introduction

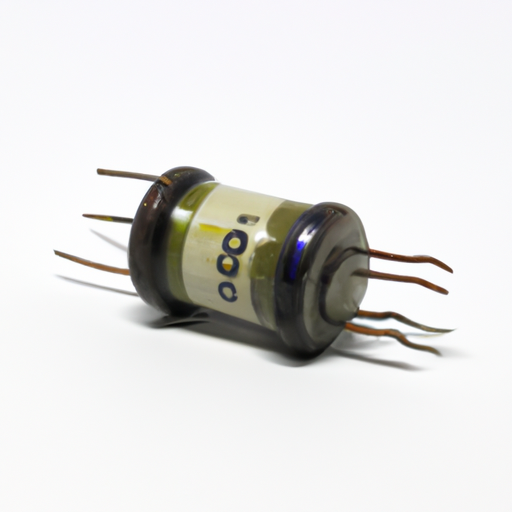

Starting capacitors are essential components in various electrical systems, particularly in applications involving electric motors. These capacitors play a crucial role in providing the necessary boost to initiate the operation of motors, ensuring they start efficiently and effectively. In this blog post, we will explore the definition of starting capacitors, their importance in electrical systems, and their practical applications across different industries.

II. Understanding Starting Capacitors

A. What is a Starting Capacitor?

A starting capacitor is a type of capacitor used to provide an initial surge of energy to an electric motor, particularly single-phase induction motors. When the motor is powered on, the starting capacitor temporarily increases the current flow, creating a phase shift in the motor's windings. This phase shift generates a rotating magnetic field, which is essential for starting the motor.

1. Definition and Function

Starting capacitors are designed to store electrical energy and release it quickly to provide the necessary torque to start the motor. They are typically rated for short-term use, as they are only needed during the initial startup phase. Once the motor reaches a certain speed, the starting capacitor is disconnected from the circuit, often by a centrifugal switch or an electronic relay.

2. Types of Starting Capacitors

There are several types of starting capacitors, including:

Electrolytic Capacitors: These are commonly used in applications requiring high capacitance values. They are polarized and must be connected correctly to avoid damage.

Non-Polarized Capacitors: These capacitors can be used in AC applications and are often found in smaller motors and appliances.

Motor Run Capacitors: While not strictly starting capacitors, these are used in conjunction with starting capacitors to improve motor efficiency during operation.

B. How Starting Capacitors Work

1. Electrical Principles

Starting capacitors operate based on the principles of capacitance and reactance. When voltage is applied, the capacitor charges and stores energy. The stored energy is then released quickly, providing a burst of current to the motor windings. This surge of current creates a magnetic field that helps the motor overcome inertia and start turning.

2. Role in Induction Motors

In single-phase induction motors, starting capacitors are vital for creating the necessary phase shift between the current in the main winding and the auxiliary winding. This phase shift is crucial for generating the rotating magnetic field that allows the motor to start. Without a starting capacitor, single-phase motors would struggle to start, leading to inefficiency and potential damage.

III. Applications of Starting Capacitors

A. HVAC Systems

Starting capacitors are widely used in HVAC systems, particularly in air conditioning units. They help the compressor motor start efficiently, ensuring that the system operates smoothly. The use of starting capacitors in HVAC systems can significantly impact energy efficiency, reducing the overall power consumption and operational costs.

B. Electric Motors

Starting capacitors are essential in various electric motors, especially single-phase induction motors. These motors are commonly found in household appliances, industrial machinery, and commercial equipment. The use of starting capacitors allows these motors to start quickly and efficiently, improving overall performance and reliability.

C. Refrigeration Systems

In refrigeration systems, starting capacitors play a critical role in the operation of compressors. Compressors require a significant amount of torque to start, and starting capacitors provide the necessary boost. By enhancing the performance and reliability of refrigeration systems, starting capacitors contribute to maintaining optimal temperatures and energy efficiency.

D. Power Tools and Equipment

Starting capacitors are also found in handheld power tools and equipment. Tools such as drills, saws, and lawnmowers often utilize starting capacitors to ensure smooth operation. The benefits of using starting capacitors in power tools include improved performance, reduced wear and tear, and increased longevity.

IV. Benefits of Using Starting Capacitors

A. Improved Starting Torque

One of the primary benefits of using starting capacitors is the improved starting torque they provide. This increased torque allows motors to overcome initial resistance and start quickly, reducing the risk of stalling or overheating.

B. Enhanced Motor Efficiency

Starting capacitors contribute to enhanced motor efficiency by ensuring that motors start smoothly and operate at optimal performance levels. This efficiency translates to lower energy consumption and reduced operational costs.

C. Reduced Electrical Noise

Starting capacitors help reduce electrical noise generated during motor startup. This reduction in noise can lead to a more pleasant working environment, particularly in residential and commercial settings.

D. Protection Against Overheating

By providing the necessary starting torque, starting capacitors help prevent motors from overheating during startup. This protection is crucial for extending the lifespan of the motor and reducing maintenance costs.

E. Cost-Effectiveness in Long-Term Use

While starting capacitors may represent an initial investment, their benefits in terms of improved efficiency, reduced wear and tear, and enhanced performance make them a cost-effective solution in the long run.

V. Challenges and Considerations

A. Selection Criteria for Starting Capacitors

When selecting starting capacitors, several criteria must be considered:

1. Voltage Ratings

It is essential to choose a starting capacitor with the appropriate voltage rating for the specific application. Using a capacitor with a lower voltage rating than required can lead to failure and potential damage to the motor.

2. Capacitance Values

The capacitance value of the starting capacitor must also be matched to the motor's requirements. An incorrect capacitance value can result in inadequate starting torque or excessive current draw.

B. Common Issues and Troubleshooting

1. Signs of Failure

Common signs of starting capacitor failure include difficulty starting the motor, unusual noises, and overheating. Regular maintenance and inspection can help identify potential issues before they lead to complete failure.

2. Replacement and Maintenance

Replacing a faulty starting capacitor is crucial for maintaining motor performance. It is essential to follow manufacturer guidelines for replacement and ensure that the new capacitor is compatible with the motor.

VI. Future Trends and Innovations

A. Advancements in Capacitor Technology

As technology continues to evolve, advancements in capacitor technology are expected to enhance the performance and efficiency of starting capacitors. Innovations may include improved materials, higher capacitance values, and better thermal management.

B. Integration with Smart Systems

The integration of starting capacitors with smart systems and IoT technology is another trend on the horizon. Smart systems can monitor motor performance and optimize the use of starting capacitors, leading to improved energy efficiency and reduced operational costs.

C. Environmental Considerations and Sustainability

As industries move towards more sustainable practices, the development of environmentally friendly starting capacitors will become increasingly important. Manufacturers are likely to focus on creating capacitors that minimize environmental impact while maintaining performance.

VII. Conclusion

In conclusion, starting capacitors play a vital role in various practical applications, particularly in electric motors, HVAC systems, refrigeration, and power tools. Their ability to provide the necessary starting torque, enhance motor efficiency, and protect against overheating makes them indispensable components in modern electrical systems. As technology continues to advance, the future of starting capacitors looks promising, with innovations that will further improve their performance and sustainability. Understanding the importance of starting capacitors and their applications can lead to better maintenance practices and more efficient use of electrical systems. We encourage further research and exploration into this essential component of electrical engineering.