What are the Product Features of Heating Resistors?

I. Introduction

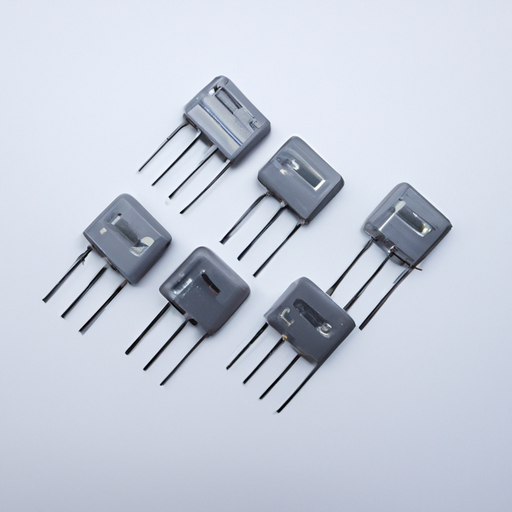

Heating resistors are essential components in various electrical and electronic applications, designed to convert electrical energy into heat through the process of resistance. These resistors play a crucial role in numerous industries, from manufacturing to consumer electronics, and their importance cannot be overstated. This article aims to explore the different types of heating resistors, their key features, material composition, applications, safety considerations, and future trends in technology.

II. Types of Heating Resistors

Heating resistors come in several types, each with unique construction, advantages, and applications.

A. Wire Wound Resistors

Wire wound resistors are made by winding a metal wire, typically nickel-chromium, around a ceramic or fiberglass core.

1. **Construction and Materials**: The wire is often coated with an insulating material to prevent short circuits.

2. **Advantages and Disadvantages**: These resistors offer high precision and stability but can be bulkier and more expensive than other types.

B. Thick Film Resistors

Thick film resistors are created by applying a thick layer of resistive material onto a substrate.

1. **Manufacturing Process**: The resistive layer is typically made from a mixture of metal oxides and glass, which is then fired to create a solid bond.

2. **Applications and Benefits**: They are widely used in applications requiring compact size and low cost, such as in consumer electronics.

C. Thin Film Resistors

Thin film resistors are similar to thick film resistors but use a much thinner layer of resistive material.

1. **Characteristics and Uses**: They offer higher precision and stability, making them suitable for applications in telecommunications and aerospace.

2. **Comparison with Other Types**: While they are more expensive, their performance in terms of temperature coefficient and noise is superior.

D. Ceramic Resistors

Ceramic resistors are made from ceramic materials that can withstand high temperatures.

1. **Properties and Applications**: They are often used in high-power applications due to their excellent thermal stability.

2. **Durability and Performance**: Their robust nature makes them ideal for industrial heating applications.

III. Key Features of Heating Resistors

Understanding the key features of heating resistors is essential for selecting the right component for specific applications.

A. Resistance Value

1. **Importance of Resistance in Heating Applications**: The resistance value determines how much heat is generated when current flows through the resistor.

2. **How Resistance Affects Heat Generation**: Higher resistance values lead to more heat generation, which is crucial for applications like heating elements.

B. Power Rating

1. **Definition and Significance**: The power rating indicates the maximum power the resistor can handle without overheating.

2. **Calculating Power Requirements**: It is essential to match the power rating with the application's requirements to ensure safety and efficiency.

C. Temperature Coefficient

1. **Explanation of Temperature Coefficient**: This coefficient indicates how much the resistance changes with temperature.

2. **Impact on Performance and Efficiency**: A low temperature coefficient is desirable for applications requiring stable performance across varying temperatures.

D. Thermal Stability

1. **Importance of Thermal Stability in Applications**: Thermal stability ensures that the resistor maintains its performance under high temperatures.

2. **Factors Affecting Thermal Stability**: Material composition and construction methods play significant roles in determining thermal stability.

E. Size and Form Factor

1. **Influence on Design and Integration**: The size of the resistor can impact the overall design of the device it is integrated into.

2. **Common Sizes and Configurations**: Heating resistors come in various sizes, from small surface-mount devices to larger, more robust components.

IV. Material Composition

The materials used in heating resistors significantly affect their performance and longevity.

A. Common Materials Used in Heating Resistors

1. **Nickel-Chromium Alloys**: Known for their excellent heat resistance and stability, these alloys are commonly used in wire wound resistors.

2. **Carbon Composition**: Carbon resistors are often used in applications requiring lower power ratings.

3. **Metal Oxide**: Metal oxide materials are used in thick film resistors, providing good thermal stability and reliability.

B. Impact of Material on Performance

1. **Conductivity and Heat Resistance**: The choice of material affects both the electrical conductivity and the ability to withstand high temperatures.

2. **Longevity and Reliability**: High-quality materials contribute to the longevity and reliability of heating resistors, reducing the need for frequent replacements.

V. Applications of Heating Resistors

Heating resistors are utilized in a wide range of applications across various industries.

A. Industrial Heating

1. **Manufacturing Processes**: Heating resistors are used in processes like soldering, welding, and material processing.

2. **Equipment and Machinery**: They are integral to industrial ovens, furnaces, and other heating equipment.

B. Consumer Electronics

1. **Home Appliances**: Commonly found in toasters, ovens, and heaters, heating resistors are vital for everyday appliances.

2. **Personal Care Devices**: Devices like hair straighteners and electric blankets rely on heating resistors for their functionality.

C. Automotive Applications

1. **Engine Heating**: Heating resistors are used to warm engine components for optimal performance.

2. **Cabin Heating**: They provide warmth in vehicle cabins, enhancing passenger comfort.

D. Medical Devices

1. **Heating Pads and Therapeutic Devices**: Used in physical therapy, heating resistors help alleviate pain and promote healing.

2. **Laboratory Equipment**: They are essential in incubators and other lab devices requiring precise temperature control.

VI. Safety Features and Considerations

Safety is paramount when dealing with heating resistors, and several features are designed to mitigate risks.

A. Overheating Protection

1. **Built-in Safety Mechanisms**: Many heating resistors come with built-in thermal cutoffs to prevent overheating.

2. **Importance of Thermal Cutoffs**: These devices automatically disconnect power when temperatures exceed safe limits, protecting both the resistor and the surrounding components.

B. Insulation and Housing

1. **Materials Used for Insulation**: High-temperature resistant materials are used to insulate heating resistors, preventing heat loss and ensuring safety.

2. **Role of Housing in Safety and Performance**: Proper housing protects the resistor from environmental factors and enhances its performance.

C. Compliance with Standards

1. **Industry Standards and Certifications**: Compliance with standards such as UL, CE, and RoHS ensures that heating resistors meet safety and environmental regulations.

2. **Importance of Compliance for Safety**: Adhering to these standards is crucial for ensuring the safety and reliability of heating resistors in various applications.

VII. Conclusion

In summary, heating resistors are vital components in a wide range of applications, from industrial heating to consumer electronics. Understanding their types, key features, material composition, and safety considerations is essential for selecting the right resistor for specific needs. As technology advances, we can expect to see innovations in heating resistor design and materials, leading to improved performance, efficiency, and safety in the future.

VIII. References

1. Academic Journals

2. Industry Reports

3. Manufacturer Specifications and Guidelines

This comprehensive overview of heating resistors highlights their significance and the various factors to consider when selecting these components for specific applications. By understanding the features and benefits of different types of heating resistors, users can make informed decisions that enhance performance and safety in their projects.

What are the Product Features of Heating Resistors?

I. Introduction

Heating resistors are essential components in various electrical and electronic applications, designed to convert electrical energy into heat through the process of resistance. These resistors play a crucial role in numerous industries, from manufacturing to consumer electronics, and their importance cannot be overstated. This article aims to explore the different types of heating resistors, their key features, material composition, applications, safety considerations, and future trends in technology.

II. Types of Heating Resistors

Heating resistors come in several types, each with unique construction, advantages, and applications.

A. Wire Wound Resistors

Wire wound resistors are made by winding a metal wire, typically nickel-chromium, around a ceramic or fiberglass core.

1. **Construction and Materials**: The wire is often coated with an insulating material to prevent short circuits.

2. **Advantages and Disadvantages**: These resistors offer high precision and stability but can be bulkier and more expensive than other types.

B. Thick Film Resistors

Thick film resistors are created by applying a thick layer of resistive material onto a substrate.

1. **Manufacturing Process**: The resistive layer is typically made from a mixture of metal oxides and glass, which is then fired to create a solid bond.

2. **Applications and Benefits**: They are widely used in applications requiring compact size and low cost, such as in consumer electronics.

C. Thin Film Resistors

Thin film resistors are similar to thick film resistors but use a much thinner layer of resistive material.

1. **Characteristics and Uses**: They offer higher precision and stability, making them suitable for applications in telecommunications and aerospace.

2. **Comparison with Other Types**: While they are more expensive, their performance in terms of temperature coefficient and noise is superior.

D. Ceramic Resistors

Ceramic resistors are made from ceramic materials that can withstand high temperatures.

1. **Properties and Applications**: They are often used in high-power applications due to their excellent thermal stability.

2. **Durability and Performance**: Their robust nature makes them ideal for industrial heating applications.

III. Key Features of Heating Resistors

Understanding the key features of heating resistors is essential for selecting the right component for specific applications.

A. Resistance Value

1. **Importance of Resistance in Heating Applications**: The resistance value determines how much heat is generated when current flows through the resistor.

2. **How Resistance Affects Heat Generation**: Higher resistance values lead to more heat generation, which is crucial for applications like heating elements.

B. Power Rating

1. **Definition and Significance**: The power rating indicates the maximum power the resistor can handle without overheating.

2. **Calculating Power Requirements**: It is essential to match the power rating with the application's requirements to ensure safety and efficiency.

C. Temperature Coefficient

1. **Explanation of Temperature Coefficient**: This coefficient indicates how much the resistance changes with temperature.

2. **Impact on Performance and Efficiency**: A low temperature coefficient is desirable for applications requiring stable performance across varying temperatures.

D. Thermal Stability

1. **Importance of Thermal Stability in Applications**: Thermal stability ensures that the resistor maintains its performance under high temperatures.

2. **Factors Affecting Thermal Stability**: Material composition and construction methods play significant roles in determining thermal stability.

E. Size and Form Factor

1. **Influence on Design and Integration**: The size of the resistor can impact the overall design of the device it is integrated into.

2. **Common Sizes and Configurations**: Heating resistors come in various sizes, from small surface-mount devices to larger, more robust components.

IV. Material Composition

The materials used in heating resistors significantly affect their performance and longevity.

A. Common Materials Used in Heating Resistors

1. **Nickel-Chromium Alloys**: Known for their excellent heat resistance and stability, these alloys are commonly used in wire wound resistors.

2. **Carbon Composition**: Carbon resistors are often used in applications requiring lower power ratings.

3. **Metal Oxide**: Metal oxide materials are used in thick film resistors, providing good thermal stability and reliability.

B. Impact of Material on Performance

1. **Conductivity and Heat Resistance**: The choice of material affects both the electrical conductivity and the ability to withstand high temperatures.

2. **Longevity and Reliability**: High-quality materials contribute to the longevity and reliability of heating resistors, reducing the need for frequent replacements.

V. Applications of Heating Resistors

Heating resistors are utilized in a wide range of applications across various industries.

A. Industrial Heating

1. **Manufacturing Processes**: Heating resistors are used in processes like soldering, welding, and material processing.

2. **Equipment and Machinery**: They are integral to industrial ovens, furnaces, and other heating equipment.

B. Consumer Electronics

1. **Home Appliances**: Commonly found in toasters, ovens, and heaters, heating resistors are vital for everyday appliances.

2. **Personal Care Devices**: Devices like hair straighteners and electric blankets rely on heating resistors for their functionality.

C. Automotive Applications

1. **Engine Heating**: Heating resistors are used to warm engine components for optimal performance.

2. **Cabin Heating**: They provide warmth in vehicle cabins, enhancing passenger comfort.

D. Medical Devices

1. **Heating Pads and Therapeutic Devices**: Used in physical therapy, heating resistors help alleviate pain and promote healing.

2. **Laboratory Equipment**: They are essential in incubators and other lab devices requiring precise temperature control.

VI. Safety Features and Considerations

Safety is paramount when dealing with heating resistors, and several features are designed to mitigate risks.

A. Overheating Protection

1. **Built-in Safety Mechanisms**: Many heating resistors come with built-in thermal cutoffs to prevent overheating.

2. **Importance of Thermal Cutoffs**: These devices automatically disconnect power when temperatures exceed safe limits, protecting both the resistor and the surrounding components.

B. Insulation and Housing

1. **Materials Used for Insulation**: High-temperature resistant materials are used to insulate heating resistors, preventing heat loss and ensuring safety.

2. **Role of Housing in Safety and Performance**: Proper housing protects the resistor from environmental factors and enhances its performance.

C. Compliance with Standards

1. **Industry Standards and Certifications**: Compliance with standards such as UL, CE, and RoHS ensures that heating resistors meet safety and environmental regulations.

2. **Importance of Compliance for Safety**: Adhering to these standards is crucial for ensuring the safety and reliability of heating resistors in various applications.

VII. Conclusion

In summary, heating resistors are vital components in a wide range of applications, from industrial heating to consumer electronics. Understanding their types, key features, material composition, and safety considerations is essential for selecting the right resistor for specific needs. As technology advances, we can expect to see innovations in heating resistor design and materials, leading to improved performance, efficiency, and safety in the future.

VIII. References

1. Academic Journals

2. Industry Reports

3. Manufacturer Specifications and Guidelines

This comprehensive overview of heating resistors highlights their significance and the various factors to consider when selecting these components for specific applications. By understanding the features and benefits of different types of heating resistors, users can make informed decisions that enhance performance and safety in their projects.