What are the Product Features of Chip Resistors?

I. Introduction

A. Definition of Chip Resistors

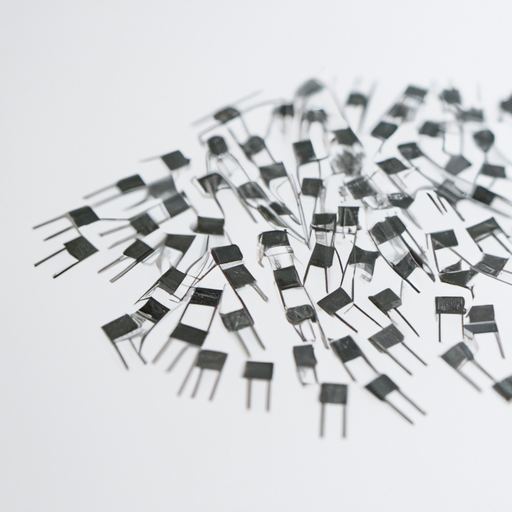

Chip resistors are small, surface-mounted resistive components used in electronic circuits to control current flow and voltage levels. Unlike traditional through-hole resistors, chip resistors are designed for automated assembly and are typically found in compact electronic devices.

B. Importance of Chip Resistors in Electronic Circuits

Chip resistors play a crucial role in modern electronics, enabling precise control of electrical signals. They are essential in various applications, from consumer electronics to industrial machinery, ensuring that devices operate efficiently and reliably.

C. Overview of the Article

This article will explore the various types of chip resistors, their key product features, material composition, manufacturing processes, applications, and future trends in technology. By understanding these aspects, designers and engineers can make informed decisions when selecting chip resistors for their projects.

II. Types of Chip Resistors

A. Thin Film Resistors

1. Characteristics

Thin film resistors are made by depositing a thin layer of resistive material onto a substrate. They offer high precision, low noise, and excellent temperature stability.

2. Applications

These resistors are commonly used in applications requiring high accuracy, such as precision measurement devices and high-frequency circuits.

B. Thick Film Resistors

1. Characteristics

Thick film resistors are created by printing a thick layer of resistive paste onto a substrate. They are generally less expensive than thin film resistors and can handle higher power levels.

2. Applications

Thick film resistors are widely used in consumer electronics, automotive applications, and general-purpose circuits.

C. Wirewound Resistors

1. Characteristics

Wirewound resistors consist of a wire wound around a core, providing high power ratings and excellent heat dissipation.

2. Applications

These resistors are often used in power applications, such as power supplies and motor controls.

D. Other Variants

1. Metal Film Resistors

Metal film resistors offer low noise and high stability, making them suitable for precision applications.

2. Carbon Film Resistors

Carbon film resistors are cost-effective and provide good performance for general applications.

III. Key Product Features of Chip Resistors

A. Resistance Value

1. Range of Resistance Values

Chip resistors are available in a wide range of resistance values, typically from a few ohms to several megaohms, allowing designers to select the appropriate resistor for their specific needs.

2. Tolerance Levels

Tolerance indicates how much the actual resistance can vary from the specified value. Common tolerance levels for chip resistors include ±1%, ±5%, and ±10%.

B. Power Rating

1. Definition and Importance

Power rating refers to the maximum amount of power a resistor can dissipate without overheating. It is crucial for ensuring the reliability and longevity of the resistor in a circuit.

2. Common Power Ratings

Chip resistors typically have power ratings ranging from 1/16 watt to 1 watt, with some high-power variants available for specialized applications.

C. Temperature Coefficient

1. Explanation of Temperature Coefficient

The temperature coefficient indicates how much the resistance value changes with temperature. A lower temperature coefficient means better stability across temperature variations.

2. Impact on Performance

Resistors with a low temperature coefficient are essential in precision applications where temperature fluctuations can significantly affect performance.

D. Size and Form Factor

1. Common Sizes (e.g., 0402, 0603, 0805)

Chip resistors come in various sizes, with common dimensions including 0402 (1.0mm x 0.5mm), 0603 (1.6mm x 0.8mm), and 0805 (2.0mm x 1.25mm). The choice of size depends on the application and available space on the circuit board.

2. Importance of Size in Design

The size of the resistor affects the overall footprint of the circuit board, making it essential for compact designs in modern electronics.

E. Voltage Rating

1. Definition and Relevance

Voltage rating indicates the maximum voltage that can be applied across the resistor without causing breakdown or failure.

2. Typical Voltage Ratings

Chip resistors typically have voltage ratings ranging from 25V to 200V, with higher ratings available for specialized applications.

F. Noise Characteristics

1. Types of Noise

Resistors can generate thermal noise, shot noise, and flicker noise, which can affect the performance of sensitive circuits.

2. Importance in Sensitive Applications

In applications such as audio equipment and precision measurement devices, low-noise resistors are critical for maintaining signal integrity.

G. Stability and Reliability

1. Factors Affecting Stability

Factors such as temperature, humidity, and mechanical stress can affect the stability of chip resistors over time.

2. Long-term Reliability Considerations

Choosing high-quality resistors with proven reliability is essential for ensuring the long-term performance of electronic devices.

IV. Material Composition

A. Conductive Materials

1. Metal Oxides

Metal oxides are commonly used in thin film resistors due to their stability and precision.

2. Carbon Composition

Carbon composition resistors are often used in thick film applications for their cost-effectiveness.

B. Substrate Materials

1. Ceramic

Ceramic substrates provide excellent thermal stability and are commonly used in high-performance resistors.

2. Epoxy

Epoxy substrates are used in lower-cost applications where high performance is not critical.

C. Coating Materials

1. Protective Coatings

Protective coatings are applied to resistors to enhance durability and resistance to environmental factors.

2. Impact on Performance

The choice of coating material can affect the resistor's performance, particularly in harsh environments.

V. Manufacturing Processes

A. Thin Film Technology

1. Overview of the Process

Thin film resistors are manufactured by depositing a thin layer of resistive material onto a substrate using techniques such as sputtering or evaporation.

2. Advantages and Disadvantages

Thin film technology offers high precision and stability but can be more expensive than other methods.

B. Thick Film Technology

1. Overview of the Process

Thick film resistors are produced by screen printing a thick layer of resistive paste onto a substrate and then firing it to create a solid film.

2. Advantages and Disadvantages

Thick film technology is cost-effective and suitable for mass production but may have lower precision compared to thin film resistors.

C. Quality Control Measures

1. Testing and Inspection

Manufacturers implement rigorous testing and inspection processes to ensure the quality and reliability of chip resistors.

2. Standards and Certifications

Compliance with industry standards and certifications, such as ISO and RoHS, is essential for ensuring product quality and safety.

VI. Applications of Chip Resistors

A. Consumer Electronics

Chip resistors are widely used in smartphones, tablets, and other consumer devices for signal processing and power management.

B. Automotive Industry

In automotive applications, chip resistors are used in control systems, sensors, and infotainment systems.

C. Telecommunications

Chip resistors are essential in telecommunications equipment, ensuring reliable signal transmission and processing.

D. Industrial Equipment

In industrial settings, chip resistors are used in control systems, automation, and monitoring devices.

E. Medical Devices

Chip resistors are critical in medical devices, where precision and reliability are paramount for patient safety.

VII. Future Trends in Chip Resistor Technology

A. Miniaturization

As electronic devices continue to shrink, the demand for smaller chip resistors will increase, driving innovation in manufacturing processes.

B. Enhanced Performance Features

Future chip resistors may incorporate advanced materials and technologies to improve performance characteristics, such as lower noise and better temperature stability.

C. Eco-friendly Materials

There is a growing trend towards using eco-friendly materials in resistor manufacturing to reduce environmental impact.

D. Smart Resistors

The development of smart resistors that can adapt their resistance based on environmental conditions or circuit requirements is an exciting area of research.

VIII. Conclusion

A. Recap of Key Features

Chip resistors are essential components in modern electronics, offering a range of features such as varying resistance values, power ratings, and sizes. Understanding these features is crucial for selecting the right resistor for specific applications.

B. Importance of Selecting the Right Chip Resistor

Choosing the appropriate chip resistor can significantly impact the performance, reliability, and longevity of electronic devices.

C. Final Thoughts on the Role of Chip Resistors in Modern Electronics

As technology continues to evolve, chip resistors will remain a fundamental component in the design and functionality of electronic circuits, driving innovation and performance in various industries.

IX. References

A. Academic Journals

- IEEE Transactions on Components, Packaging and Manufacturing Technology

- Journal of Electronic Materials

B. Industry Reports

- Market Research Reports on Passive Components

- Industry Analysis from Electronics Weekly

C. Manufacturer Specifications

- Datasheets from leading resistor manufacturers

- Technical documentation from component suppliers

This comprehensive overview of chip resistors highlights their significance in electronic design and the various factors that influence their selection and application. Understanding these elements is essential for engineers and designers aiming to create efficient and reliable electronic systems.

What are the Product Features of Chip Resistors?

I. Introduction

A. Definition of Chip Resistors

Chip resistors are small, surface-mounted resistive components used in electronic circuits to control current flow and voltage levels. Unlike traditional through-hole resistors, chip resistors are designed for automated assembly and are typically found in compact electronic devices.

B. Importance of Chip Resistors in Electronic Circuits

Chip resistors play a crucial role in modern electronics, enabling precise control of electrical signals. They are essential in various applications, from consumer electronics to industrial machinery, ensuring that devices operate efficiently and reliably.

C. Overview of the Article

This article will explore the various types of chip resistors, their key product features, material composition, manufacturing processes, applications, and future trends in technology. By understanding these aspects, designers and engineers can make informed decisions when selecting chip resistors for their projects.

II. Types of Chip Resistors

A. Thin Film Resistors

1. Characteristics

Thin film resistors are made by depositing a thin layer of resistive material onto a substrate. They offer high precision, low noise, and excellent temperature stability.

2. Applications

These resistors are commonly used in applications requiring high accuracy, such as precision measurement devices and high-frequency circuits.

B. Thick Film Resistors

1. Characteristics

Thick film resistors are created by printing a thick layer of resistive paste onto a substrate. They are generally less expensive than thin film resistors and can handle higher power levels.

2. Applications

Thick film resistors are widely used in consumer electronics, automotive applications, and general-purpose circuits.

C. Wirewound Resistors

1. Characteristics

Wirewound resistors consist of a wire wound around a core, providing high power ratings and excellent heat dissipation.

2. Applications

These resistors are often used in power applications, such as power supplies and motor controls.

D. Other Variants

1. Metal Film Resistors

Metal film resistors offer low noise and high stability, making them suitable for precision applications.

2. Carbon Film Resistors

Carbon film resistors are cost-effective and provide good performance for general applications.

III. Key Product Features of Chip Resistors

A. Resistance Value

1. Range of Resistance Values

Chip resistors are available in a wide range of resistance values, typically from a few ohms to several megaohms, allowing designers to select the appropriate resistor for their specific needs.

2. Tolerance Levels

Tolerance indicates how much the actual resistance can vary from the specified value. Common tolerance levels for chip resistors include ±1%, ±5%, and ±10%.

B. Power Rating

1. Definition and Importance

Power rating refers to the maximum amount of power a resistor can dissipate without overheating. It is crucial for ensuring the reliability and longevity of the resistor in a circuit.

2. Common Power Ratings

Chip resistors typically have power ratings ranging from 1/16 watt to 1 watt, with some high-power variants available for specialized applications.

C. Temperature Coefficient

1. Explanation of Temperature Coefficient

The temperature coefficient indicates how much the resistance value changes with temperature. A lower temperature coefficient means better stability across temperature variations.

2. Impact on Performance

Resistors with a low temperature coefficient are essential in precision applications where temperature fluctuations can significantly affect performance.

D. Size and Form Factor

1. Common Sizes (e.g., 0402, 0603, 0805)

Chip resistors come in various sizes, with common dimensions including 0402 (1.0mm x 0.5mm), 0603 (1.6mm x 0.8mm), and 0805 (2.0mm x 1.25mm). The choice of size depends on the application and available space on the circuit board.

2. Importance of Size in Design

The size of the resistor affects the overall footprint of the circuit board, making it essential for compact designs in modern electronics.

E. Voltage Rating

1. Definition and Relevance

Voltage rating indicates the maximum voltage that can be applied across the resistor without causing breakdown or failure.

2. Typical Voltage Ratings

Chip resistors typically have voltage ratings ranging from 25V to 200V, with higher ratings available for specialized applications.

F. Noise Characteristics

1. Types of Noise

Resistors can generate thermal noise, shot noise, and flicker noise, which can affect the performance of sensitive circuits.

2. Importance in Sensitive Applications

In applications such as audio equipment and precision measurement devices, low-noise resistors are critical for maintaining signal integrity.

G. Stability and Reliability

1. Factors Affecting Stability

Factors such as temperature, humidity, and mechanical stress can affect the stability of chip resistors over time.

2. Long-term Reliability Considerations

Choosing high-quality resistors with proven reliability is essential for ensuring the long-term performance of electronic devices.

IV. Material Composition

A. Conductive Materials

1. Metal Oxides

Metal oxides are commonly used in thin film resistors due to their stability and precision.

2. Carbon Composition

Carbon composition resistors are often used in thick film applications for their cost-effectiveness.

B. Substrate Materials

1. Ceramic

Ceramic substrates provide excellent thermal stability and are commonly used in high-performance resistors.

2. Epoxy

Epoxy substrates are used in lower-cost applications where high performance is not critical.

C. Coating Materials

1. Protective Coatings

Protective coatings are applied to resistors to enhance durability and resistance to environmental factors.

2. Impact on Performance

The choice of coating material can affect the resistor's performance, particularly in harsh environments.

V. Manufacturing Processes

A. Thin Film Technology

1. Overview of the Process

Thin film resistors are manufactured by depositing a thin layer of resistive material onto a substrate using techniques such as sputtering or evaporation.

2. Advantages and Disadvantages

Thin film technology offers high precision and stability but can be more expensive than other methods.

B. Thick Film Technology

1. Overview of the Process

Thick film resistors are produced by screen printing a thick layer of resistive paste onto a substrate and then firing it to create a solid film.

2. Advantages and Disadvantages

Thick film technology is cost-effective and suitable for mass production but may have lower precision compared to thin film resistors.

C. Quality Control Measures

1. Testing and Inspection

Manufacturers implement rigorous testing and inspection processes to ensure the quality and reliability of chip resistors.

2. Standards and Certifications

Compliance with industry standards and certifications, such as ISO and RoHS, is essential for ensuring product quality and safety.

VI. Applications of Chip Resistors

A. Consumer Electronics

Chip resistors are widely used in smartphones, tablets, and other consumer devices for signal processing and power management.

B. Automotive Industry

In automotive applications, chip resistors are used in control systems, sensors, and infotainment systems.

C. Telecommunications

Chip resistors are essential in telecommunications equipment, ensuring reliable signal transmission and processing.

D. Industrial Equipment

In industrial settings, chip resistors are used in control systems, automation, and monitoring devices.

E. Medical Devices

Chip resistors are critical in medical devices, where precision and reliability are paramount for patient safety.

VII. Future Trends in Chip Resistor Technology

A. Miniaturization

As electronic devices continue to shrink, the demand for smaller chip resistors will increase, driving innovation in manufacturing processes.

B. Enhanced Performance Features

Future chip resistors may incorporate advanced materials and technologies to improve performance characteristics, such as lower noise and better temperature stability.

C. Eco-friendly Materials

There is a growing trend towards using eco-friendly materials in resistor manufacturing to reduce environmental impact.

D. Smart Resistors

The development of smart resistors that can adapt their resistance based on environmental conditions or circuit requirements is an exciting area of research.

VIII. Conclusion

A. Recap of Key Features

Chip resistors are essential components in modern electronics, offering a range of features such as varying resistance values, power ratings, and sizes. Understanding these features is crucial for selecting the right resistor for specific applications.

B. Importance of Selecting the Right Chip Resistor

Choosing the appropriate chip resistor can significantly impact the performance, reliability, and longevity of electronic devices.

C. Final Thoughts on the Role of Chip Resistors in Modern Electronics

As technology continues to evolve, chip resistors will remain a fundamental component in the design and functionality of electronic circuits, driving innovation and performance in various industries.

IX. References

A. Academic Journals

- IEEE Transactions on Components, Packaging and Manufacturing Technology

- Journal of Electronic Materials

B. Industry Reports

- Market Research Reports on Passive Components

- Industry Analysis from Electronics Weekly

C. Manufacturer Specifications

- Datasheets from leading resistor manufacturers

- Technical documentation from component suppliers

This comprehensive overview of chip resistors highlights their significance in electronic design and the various factors that influence their selection and application. Understanding these elements is essential for engineers and designers aiming to create efficient and reliable electronic systems.