What Kind of Product is a Capacitor Cabinet?

I. Introduction

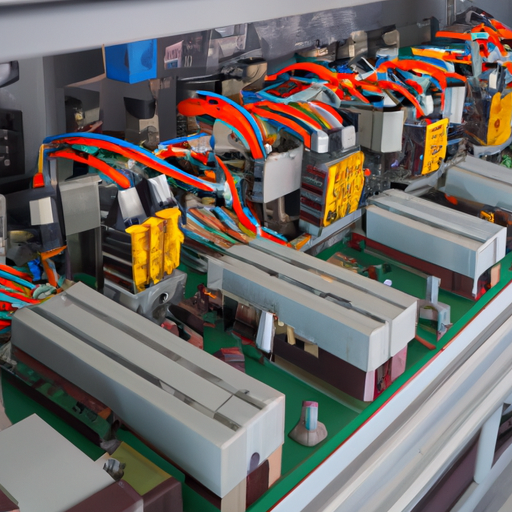

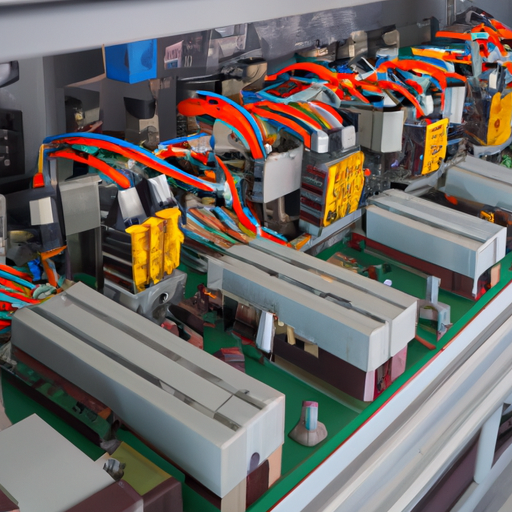

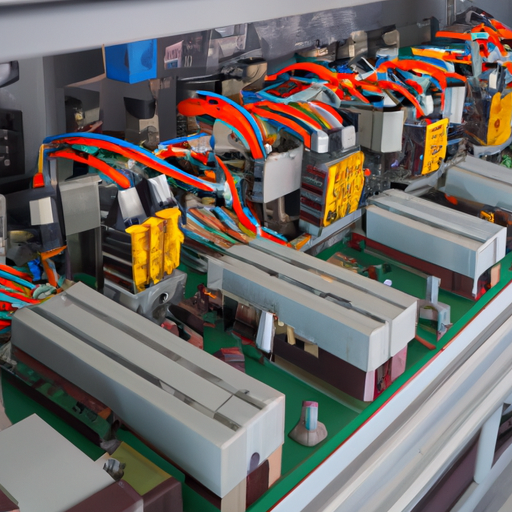

In the realm of electrical engineering, capacitor cabinets play a crucial role in enhancing the efficiency and reliability of electrical systems. A capacitor cabinet is a specialized enclosure that houses capacitor banks, control systems, and protection devices, all designed to improve power quality and manage electrical loads. This article will delve into the definition, components, applications, benefits, installation, maintenance, challenges, and future trends of capacitor cabinets, providing a comprehensive understanding of this essential product.

II. Understanding Capacitors

A. Basic Principles of Capacitors

At its core, a capacitor is an electrical component that stores energy in an electric field. It consists of two conductive plates separated by an insulating material, known as a dielectric. When voltage is applied across the plates, an electric field is created, allowing the capacitor to store energy. Capacitors are classified into various types, including ceramic, electrolytic, film, and tantalum capacitors, each serving different purposes in electrical systems.

B. Role of Capacitors in Electrical Systems

Capacitors serve several vital functions in electrical systems:

1. **Energy Storage**: Capacitors can store and release energy quickly, making them essential for applications requiring rapid energy discharge, such as in power electronics and signal processing.

2. **Power Factor Correction**: In alternating current (AC) systems, capacitors help improve the power factor by compensating for inductive loads, which can lead to more efficient energy usage.

3. **Voltage Regulation**: Capacitors can stabilize voltage levels in electrical systems, ensuring that equipment operates within specified voltage ranges, thereby preventing damage and improving performance.

III. What is a Capacitor Cabinet?

A. Definition and Purpose

A capacitor cabinet is an enclosure that contains multiple capacitor banks, control systems, and protective devices. Its primary purpose is to manage and optimize the performance of capacitors within electrical systems, ensuring that they operate efficiently and safely.

B. Components of a Capacitor Cabinet

1. **Capacitor Banks**: These are groups of capacitors connected in parallel or series to achieve the desired capacitance and voltage ratings. Capacitor banks are the heart of the cabinet, providing the necessary reactive power for power factor correction and voltage stabilization.

2. **Control Systems**: These systems monitor and manage the operation of the capacitor banks, ensuring they engage and disengage as needed based on the electrical load and power factor requirements.

3. **Protection Devices**: Capacitor cabinets are equipped with various protection devices, such as fuses, circuit breakers, and surge protectors, to safeguard the capacitors and the overall electrical system from faults and overvoltage conditions.

C. Types of Capacitor Cabinets

1. **Indoor vs. Outdoor Cabinets**: Indoor capacitor cabinets are designed for installation within buildings, while outdoor cabinets are built to withstand environmental conditions, such as rain, snow, and extreme temperatures.

2. **Fixed vs. Automatic Capacitor Banks**: Fixed capacitor banks provide a constant level of reactive power, while automatic capacitor banks can adjust their output based on real-time load conditions, offering greater flexibility and efficiency.

IV. Applications of Capacitor Cabinets

A. Industrial Applications

Capacitor cabinets are widely used in industrial settings, such as manufacturing facilities and power plants. In these environments, they help improve power factor, reduce energy costs, and enhance the reliability of electrical systems.

B. Commercial Applications

In commercial buildings, such as shopping malls and office complexes, capacitor cabinets play a vital role in managing electrical loads, ensuring that lighting, HVAC systems, and other equipment operate efficiently.

C. Utility Applications

Utility companies utilize capacitor cabinets in power distribution networks to maintain voltage levels and improve the overall efficiency of the grid. They are also essential in renewable energy systems, where they help manage the variability of power generation from sources like solar and wind.

V. Benefits of Using Capacitor Cabinets

A. Improved Power Factor

One of the primary benefits of capacitor cabinets is their ability to improve the power factor of electrical systems. A higher power factor indicates more efficient use of electrical power, reducing energy losses and lowering utility bills.

B. Reduced Energy Costs

By improving the power factor and reducing reactive power demand, capacitor cabinets can lead to significant energy cost savings for businesses and industrial facilities. Many utility companies offer incentives for customers who improve their power factor, further enhancing the financial benefits.

C. Enhanced System Reliability

Capacitor cabinets contribute to the overall reliability of electrical systems by stabilizing voltage levels and reducing the risk of equipment failure. This reliability is crucial for industries that rely on continuous operation and cannot afford downtime.

D. Increased Equipment Lifespan

By maintaining optimal voltage levels and reducing electrical stress on equipment, capacitor cabinets can extend the lifespan of electrical devices, such as motors, transformers, and other critical components.

VI. Installation and Maintenance of Capacitor Cabinets

A. Installation Considerations

1. **Site Assessment**: Before installation, a thorough site assessment is necessary to determine the optimal location for the capacitor cabinet, considering factors such as accessibility, environmental conditions, and proximity to electrical loads.

2. **Electrical Connections**: Proper electrical connections are crucial for the safe and efficient operation of capacitor cabinets. This includes ensuring that the cabinet is correctly grounded and that all connections are secure and compliant with electrical codes.

B. Maintenance Practices

1. **Regular Inspections**: Routine inspections of capacitor cabinets are essential to identify potential issues before they escalate. This includes checking for signs of wear, corrosion, and loose connections.

2. **Troubleshooting Common Issues**: Common issues with capacitor cabinets may include overheating, blown fuses, or malfunctioning control systems. Having a troubleshooting plan in place can help address these problems quickly.

3. **Safety Precautions**: Working with electrical equipment can be hazardous. It is essential to follow safety protocols, including wearing appropriate personal protective equipment (PPE) and ensuring that the cabinet is de-energized before performing maintenance.

VII. Challenges and Considerations

A. Potential Issues with Capacitor Cabinets

1. **Harmonics and Resonance**: Capacitor cabinets can introduce harmonics into the electrical system, which can lead to resonance issues and equipment damage. Proper design and filtering techniques are necessary to mitigate these effects.

2. **Overvoltage Conditions**: In some cases, capacitor banks can cause overvoltage conditions, particularly during light load periods. Protective devices and control systems must be in place to prevent these situations.

B. Regulatory and Compliance Considerations

Capacitor cabinets must comply with various industry standards and regulations, including those set by the Institute of Electrical and Electronics Engineers (IEEE) and the National Electrical Manufacturers Association (NEMA). Ensuring compliance is essential for safety and reliability.

C. Future Trends in Capacitor Technology

As technology advances, capacitor cabinets are evolving to incorporate smart features, such as remote monitoring and automated control systems. These innovations will enhance their efficiency and adaptability in an increasingly complex electrical landscape.

VIII. Conclusion

Capacitor cabinets are essential components in modern electrical systems, providing numerous benefits, including improved power factor, reduced energy costs, and enhanced reliability. As industries continue to prioritize energy efficiency and sustainability, the role of capacitor cabinets will only become more significant. By understanding their function, applications, and maintenance requirements, businesses can leverage capacitor cabinets to optimize their electrical systems and contribute to a more efficient future.

IX. References

For further reading and resources on capacitor cabinets, consider exploring the following:

- IEEE Standards for Capacitor Banks

- NEMA Guidelines for Capacitor Equipment

- Industry publications on power factor correction and energy efficiency

By staying informed about the latest developments in capacitor technology and best practices, professionals can ensure that their electrical systems remain efficient, reliable, and compliant with industry standards.

What Kind of Product is a Capacitor Cabinet?

I. Introduction

In the realm of electrical engineering, capacitor cabinets play a crucial role in enhancing the efficiency and reliability of electrical systems. A capacitor cabinet is a specialized enclosure that houses capacitor banks, control systems, and protection devices, all designed to improve power quality and manage electrical loads. This article will delve into the definition, components, applications, benefits, installation, maintenance, challenges, and future trends of capacitor cabinets, providing a comprehensive understanding of this essential product.

II. Understanding Capacitors

A. Basic Principles of Capacitors

At its core, a capacitor is an electrical component that stores energy in an electric field. It consists of two conductive plates separated by an insulating material, known as a dielectric. When voltage is applied across the plates, an electric field is created, allowing the capacitor to store energy. Capacitors are classified into various types, including ceramic, electrolytic, film, and tantalum capacitors, each serving different purposes in electrical systems.

B. Role of Capacitors in Electrical Systems

Capacitors serve several vital functions in electrical systems:

1. **Energy Storage**: Capacitors can store and release energy quickly, making them essential for applications requiring rapid energy discharge, such as in power electronics and signal processing.

2. **Power Factor Correction**: In alternating current (AC) systems, capacitors help improve the power factor by compensating for inductive loads, which can lead to more efficient energy usage.

3. **Voltage Regulation**: Capacitors can stabilize voltage levels in electrical systems, ensuring that equipment operates within specified voltage ranges, thereby preventing damage and improving performance.

III. What is a Capacitor Cabinet?

A. Definition and Purpose

A capacitor cabinet is an enclosure that contains multiple capacitor banks, control systems, and protective devices. Its primary purpose is to manage and optimize the performance of capacitors within electrical systems, ensuring that they operate efficiently and safely.

B. Components of a Capacitor Cabinet

1. **Capacitor Banks**: These are groups of capacitors connected in parallel or series to achieve the desired capacitance and voltage ratings. Capacitor banks are the heart of the cabinet, providing the necessary reactive power for power factor correction and voltage stabilization.

2. **Control Systems**: These systems monitor and manage the operation of the capacitor banks, ensuring they engage and disengage as needed based on the electrical load and power factor requirements.

3. **Protection Devices**: Capacitor cabinets are equipped with various protection devices, such as fuses, circuit breakers, and surge protectors, to safeguard the capacitors and the overall electrical system from faults and overvoltage conditions.

C. Types of Capacitor Cabinets

1. **Indoor vs. Outdoor Cabinets**: Indoor capacitor cabinets are designed for installation within buildings, while outdoor cabinets are built to withstand environmental conditions, such as rain, snow, and extreme temperatures.

2. **Fixed vs. Automatic Capacitor Banks**: Fixed capacitor banks provide a constant level of reactive power, while automatic capacitor banks can adjust their output based on real-time load conditions, offering greater flexibility and efficiency.

IV. Applications of Capacitor Cabinets

A. Industrial Applications

Capacitor cabinets are widely used in industrial settings, such as manufacturing facilities and power plants. In these environments, they help improve power factor, reduce energy costs, and enhance the reliability of electrical systems.

B. Commercial Applications

In commercial buildings, such as shopping malls and office complexes, capacitor cabinets play a vital role in managing electrical loads, ensuring that lighting, HVAC systems, and other equipment operate efficiently.

C. Utility Applications

Utility companies utilize capacitor cabinets in power distribution networks to maintain voltage levels and improve the overall efficiency of the grid. They are also essential in renewable energy systems, where they help manage the variability of power generation from sources like solar and wind.

V. Benefits of Using Capacitor Cabinets

A. Improved Power Factor

One of the primary benefits of capacitor cabinets is their ability to improve the power factor of electrical systems. A higher power factor indicates more efficient use of electrical power, reducing energy losses and lowering utility bills.

B. Reduced Energy Costs

By improving the power factor and reducing reactive power demand, capacitor cabinets can lead to significant energy cost savings for businesses and industrial facilities. Many utility companies offer incentives for customers who improve their power factor, further enhancing the financial benefits.

C. Enhanced System Reliability

Capacitor cabinets contribute to the overall reliability of electrical systems by stabilizing voltage levels and reducing the risk of equipment failure. This reliability is crucial for industries that rely on continuous operation and cannot afford downtime.

D. Increased Equipment Lifespan

By maintaining optimal voltage levels and reducing electrical stress on equipment, capacitor cabinets can extend the lifespan of electrical devices, such as motors, transformers, and other critical components.

VI. Installation and Maintenance of Capacitor Cabinets

A. Installation Considerations

1. **Site Assessment**: Before installation, a thorough site assessment is necessary to determine the optimal location for the capacitor cabinet, considering factors such as accessibility, environmental conditions, and proximity to electrical loads.

2. **Electrical Connections**: Proper electrical connections are crucial for the safe and efficient operation of capacitor cabinets. This includes ensuring that the cabinet is correctly grounded and that all connections are secure and compliant with electrical codes.

B. Maintenance Practices

1. **Regular Inspections**: Routine inspections of capacitor cabinets are essential to identify potential issues before they escalate. This includes checking for signs of wear, corrosion, and loose connections.

2. **Troubleshooting Common Issues**: Common issues with capacitor cabinets may include overheating, blown fuses, or malfunctioning control systems. Having a troubleshooting plan in place can help address these problems quickly.

3. **Safety Precautions**: Working with electrical equipment can be hazardous. It is essential to follow safety protocols, including wearing appropriate personal protective equipment (PPE) and ensuring that the cabinet is de-energized before performing maintenance.

VII. Challenges and Considerations

A. Potential Issues with Capacitor Cabinets

1. **Harmonics and Resonance**: Capacitor cabinets can introduce harmonics into the electrical system, which can lead to resonance issues and equipment damage. Proper design and filtering techniques are necessary to mitigate these effects.

2. **Overvoltage Conditions**: In some cases, capacitor banks can cause overvoltage conditions, particularly during light load periods. Protective devices and control systems must be in place to prevent these situations.

B. Regulatory and Compliance Considerations

Capacitor cabinets must comply with various industry standards and regulations, including those set by the Institute of Electrical and Electronics Engineers (IEEE) and the National Electrical Manufacturers Association (NEMA). Ensuring compliance is essential for safety and reliability.

C. Future Trends in Capacitor Technology

As technology advances, capacitor cabinets are evolving to incorporate smart features, such as remote monitoring and automated control systems. These innovations will enhance their efficiency and adaptability in an increasingly complex electrical landscape.

VIII. Conclusion

Capacitor cabinets are essential components in modern electrical systems, providing numerous benefits, including improved power factor, reduced energy costs, and enhanced reliability. As industries continue to prioritize energy efficiency and sustainability, the role of capacitor cabinets will only become more significant. By understanding their function, applications, and maintenance requirements, businesses can leverage capacitor cabinets to optimize their electrical systems and contribute to a more efficient future.

IX. References

For further reading and resources on capacitor cabinets, consider exploring the following:

- IEEE Standards for Capacitor Banks

- NEMA Guidelines for Capacitor Equipment

- Industry publications on power factor correction and energy efficiency

By staying informed about the latest developments in capacitor technology and best practices, professionals can ensure that their electrical systems remain efficient, reliable, and compliant with industry standards.