What are the Popular Models of Resistor Starting?

I. Introduction

In the realm of electrical engineering, the methods used to start motors and other electrical devices are crucial for ensuring efficiency and longevity. One such method is resistor starting, a technique that employs resistors to control the initial current flow to a motor. This blog post will delve into the popular models of resistor starting, exploring their principles, applications, advantages, and limitations.

II. Understanding Resistor Starting

A. Explanation of Resistor Starting

Resistor starting is a method used primarily for starting induction motors. The basic principle involves connecting resistors in series with the motor windings during the startup phase. This configuration limits the inrush current, which can be several times higher than the motor's rated current. By controlling this initial surge, resistor starting helps to prevent damage to the motor and the electrical supply system.

1. Basic Principles

When a motor is started, it draws a high inrush current due to the low impedance of the stator windings. Resistor starting mitigates this by introducing resistance into the circuit, which reduces the current flow. As the motor accelerates and reaches a certain speed, the resistors can be bypassed, allowing the motor to operate at full capacity.

2. Applications in Electrical Systems

Resistor starting is commonly used in applications where high starting torque is required, such as in large industrial motors, pumps, and compressors. It is particularly beneficial in systems where a sudden surge of current could lead to voltage drops or damage to other connected equipment.

B. Comparison with Other Starting Methods

Resistor starting is one of several methods available for motor starting. Other common techniques include:

1. Direct-on-line (DOL) Starting

DOL starting connects the motor directly to the power supply, resulting in a high inrush current. While simple and cost-effective, this method can lead to mechanical stress and electrical disturbances.

2. Star-Delta Starting

This method involves initially connecting the motor in a star configuration to reduce voltage and current during startup. After reaching a certain speed, the motor is switched to a delta configuration for normal operation. While effective, it requires additional contactors and can be complex to implement.

3. Soft Starters

Soft starters use electronic controls to gradually increase the voltage supplied to the motor, thereby controlling the starting current. This method is more sophisticated and can provide better control over the starting process, but it may be more expensive than resistor starting.

III. Popular Models of Resistor Starting

Several models of resistor starting are commonly used in various applications. Each model has its unique components, advantages, and disadvantages.

A. Basic Resistor Starting Model

1. Description and Components

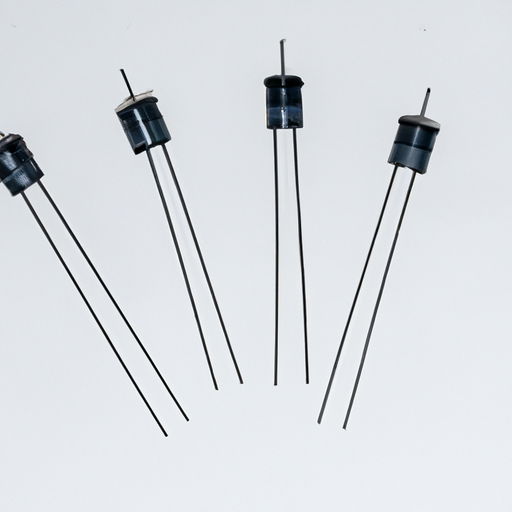

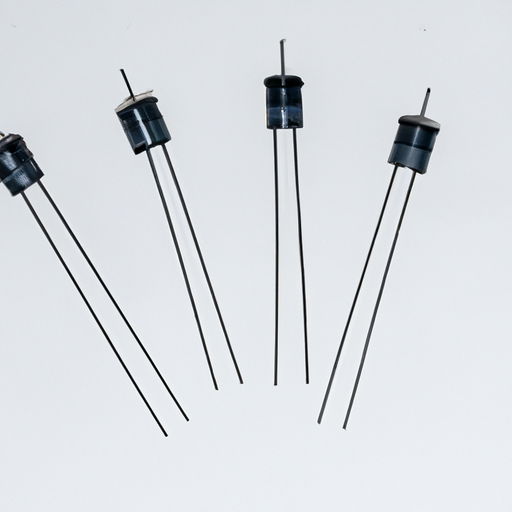

The basic resistor starting model consists of a set of resistors connected in series with the motor windings. These resistors are typically made of wire-wound or carbon materials and are designed to handle the heat generated during operation.

2. Advantages and Disadvantages

**Advantages:**

- Simple design and easy to implement.

- Cost-effective for many applications.

- Reduces inrush current effectively.

**Disadvantages:**

- Generates heat, requiring adequate cooling measures.

- Limited control over starting torque compared to more advanced methods.

B. Variable Resistor Starting Model

1. Description and Components

The variable resistor starting model incorporates adjustable resistors, allowing for fine-tuning of the resistance based on the specific requirements of the motor and application.

2. Advantages and Disadvantages

**Advantages:**

- Greater flexibility in controlling starting current and torque.

- Can be adjusted for different load conditions.

**Disadvantages:**

- More complex and potentially more expensive than the basic model.

- Requires careful monitoring and adjustment.

C. Series Resistor Starting Model

1. Description and Components

In the series resistor starting model, multiple resistors are connected in series with the motor. This model can be designed to include a switch or relay that allows for the gradual removal of resistors as the motor accelerates.

2. Advantages and Disadvantages

**Advantages:**

- Provides a controlled starting process.

- Can be tailored to specific motor characteristics.

**Disadvantages:**

- Increased complexity in design and implementation.

- Potential for overheating if not properly managed.

D. Automatic Resistor Starting Model

1. Description and Components

The automatic resistor starting model uses sensors and control systems to automatically adjust the resistance based on the motor's speed and load conditions. This model is often integrated with modern control systems for enhanced performance.

2. Advantages and Disadvantages

**Advantages:**

- Offers optimal control over starting conditions.

- Reduces the need for manual adjustments.

**Disadvantages:**

- Higher initial cost due to advanced components.

- Requires more sophisticated maintenance and troubleshooting.

IV. Applications of Resistor Starting Models

Resistor starting models find applications across various sectors, including industrial, commercial, and residential settings.

A. Industrial Applications

1. Motors and Generators

In industrial environments, resistor starting is commonly used for large motors and generators, where controlling inrush current is critical for system stability.

2. Pumps and Compressors

Pumps and compressors often require high starting torque, making resistor starting an ideal choice to ensure smooth operation without damaging the equipment.

B. Commercial Applications

1. HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems frequently utilize resistor starting to manage the starting currents of large motors, ensuring efficient operation.

2. Elevators and Escalators

In elevators and escalators, resistor starting helps to provide a smooth and controlled start, enhancing passenger comfort and safety.

C. Residential Applications

1. Home Appliances

Some home appliances, such as washing machines and refrigerators, may use resistor starting to manage motor operation effectively.

2. Small-Scale Machinery

Small-scale machinery, including woodworking tools and garden equipment, can benefit from resistor starting to ensure reliable performance.

V. Advantages of Resistor Starting

Resistor starting offers several advantages that make it a popular choice in various applications.

A. Reduced Inrush Current

By limiting the initial current flow, resistor starting helps to prevent voltage drops and protects both the motor and the electrical supply system.

B. Improved Motor Life and Performance

Controlling the starting current reduces mechanical stress on the motor, leading to improved longevity and performance.

C. Enhanced Control Over Starting Torque

Resistor starting allows for better control over the starting torque, making it suitable for applications requiring high torque at startup.

D. Cost-Effectiveness in Certain Applications

For many applications, resistor starting is a cost-effective solution compared to more complex starting methods.

VI. Challenges and Limitations of Resistor Starting

Despite its advantages, resistor starting also presents several challenges and limitations.

A. Heat Generation and Dissipation

The resistors used in this method generate heat, which must be managed to prevent damage to the components and surrounding equipment.

B. Complexity in Design and Implementation

Some models of resistor starting can be complex to design and implement, requiring careful planning and engineering.

C. Maintenance Requirements

Regular maintenance is necessary to ensure the resistors and associated components function correctly and safely.

D. Limited Use Cases

While effective in many applications, resistor starting may not be suitable for all motor types or operational conditions.

VII. Future Trends in Resistor Starting Technology

As technology advances, several trends are emerging in the field of resistor starting.

A. Integration with Smart Technologies

The integration of smart technologies and IoT devices is expected to enhance the control and monitoring of resistor starting systems, improving efficiency and performance.

B. Advances in Materials and Components

New materials and components are being developed to improve the efficiency and heat management of resistor starting systems.

C. Potential for Energy Efficiency Improvements

As energy efficiency becomes increasingly important, resistor starting technology may evolve to provide even greater energy savings in various applications.

VIII. Conclusion

In summary, resistor starting is a vital technique in electrical engineering, offering a reliable method for controlling motor startup. With various models available, each with its unique advantages and limitations, understanding these options is essential for selecting the right method for specific applications. As technology continues to advance, the role of resistor starting in modern electrical systems will likely evolve, further enhancing its importance in the industry.

IX. References

A. Suggested Reading

- "Electric Motor Control" by Frank D. Petruzella

- "Electrical Engineering: Principles and Applications" by Allan R. Hambley

B. Relevant Industry Standards and Guidelines

- National Electrical Manufacturers Association (NEMA) Standards

- Institute of Electrical and Electronics Engineers (IEEE) Standards

C. Academic Journals and Articles on Resistor Starting

- IEEE Transactions on Industry Applications

- Journal of Electrical Engineering & Technology

By understanding the popular models of resistor starting, engineers and technicians can make informed decisions that enhance the performance and reliability of electrical systems.

What are the Popular Models of Resistor Starting?

I. Introduction

In the realm of electrical engineering, the methods used to start motors and other electrical devices are crucial for ensuring efficiency and longevity. One such method is resistor starting, a technique that employs resistors to control the initial current flow to a motor. This blog post will delve into the popular models of resistor starting, exploring their principles, applications, advantages, and limitations.

II. Understanding Resistor Starting

A. Explanation of Resistor Starting

Resistor starting is a method used primarily for starting induction motors. The basic principle involves connecting resistors in series with the motor windings during the startup phase. This configuration limits the inrush current, which can be several times higher than the motor's rated current. By controlling this initial surge, resistor starting helps to prevent damage to the motor and the electrical supply system.

1. Basic Principles

When a motor is started, it draws a high inrush current due to the low impedance of the stator windings. Resistor starting mitigates this by introducing resistance into the circuit, which reduces the current flow. As the motor accelerates and reaches a certain speed, the resistors can be bypassed, allowing the motor to operate at full capacity.

2. Applications in Electrical Systems

Resistor starting is commonly used in applications where high starting torque is required, such as in large industrial motors, pumps, and compressors. It is particularly beneficial in systems where a sudden surge of current could lead to voltage drops or damage to other connected equipment.

B. Comparison with Other Starting Methods

Resistor starting is one of several methods available for motor starting. Other common techniques include:

1. Direct-on-line (DOL) Starting

DOL starting connects the motor directly to the power supply, resulting in a high inrush current. While simple and cost-effective, this method can lead to mechanical stress and electrical disturbances.

2. Star-Delta Starting

This method involves initially connecting the motor in a star configuration to reduce voltage and current during startup. After reaching a certain speed, the motor is switched to a delta configuration for normal operation. While effective, it requires additional contactors and can be complex to implement.

3. Soft Starters

Soft starters use electronic controls to gradually increase the voltage supplied to the motor, thereby controlling the starting current. This method is more sophisticated and can provide better control over the starting process, but it may be more expensive than resistor starting.

III. Popular Models of Resistor Starting

Several models of resistor starting are commonly used in various applications. Each model has its unique components, advantages, and disadvantages.

A. Basic Resistor Starting Model

1. Description and Components

The basic resistor starting model consists of a set of resistors connected in series with the motor windings. These resistors are typically made of wire-wound or carbon materials and are designed to handle the heat generated during operation.

2. Advantages and Disadvantages

**Advantages:**

- Simple design and easy to implement.

- Cost-effective for many applications.

- Reduces inrush current effectively.

**Disadvantages:**

- Generates heat, requiring adequate cooling measures.

- Limited control over starting torque compared to more advanced methods.

B. Variable Resistor Starting Model

1. Description and Components

The variable resistor starting model incorporates adjustable resistors, allowing for fine-tuning of the resistance based on the specific requirements of the motor and application.

2. Advantages and Disadvantages

**Advantages:**

- Greater flexibility in controlling starting current and torque.

- Can be adjusted for different load conditions.

**Disadvantages:**

- More complex and potentially more expensive than the basic model.

- Requires careful monitoring and adjustment.

C. Series Resistor Starting Model

1. Description and Components

In the series resistor starting model, multiple resistors are connected in series with the motor. This model can be designed to include a switch or relay that allows for the gradual removal of resistors as the motor accelerates.

2. Advantages and Disadvantages

**Advantages:**

- Provides a controlled starting process.

- Can be tailored to specific motor characteristics.

**Disadvantages:**

- Increased complexity in design and implementation.

- Potential for overheating if not properly managed.

D. Automatic Resistor Starting Model

1. Description and Components

The automatic resistor starting model uses sensors and control systems to automatically adjust the resistance based on the motor's speed and load conditions. This model is often integrated with modern control systems for enhanced performance.

2. Advantages and Disadvantages

**Advantages:**

- Offers optimal control over starting conditions.

- Reduces the need for manual adjustments.

**Disadvantages:**

- Higher initial cost due to advanced components.

- Requires more sophisticated maintenance and troubleshooting.

IV. Applications of Resistor Starting Models

Resistor starting models find applications across various sectors, including industrial, commercial, and residential settings.

A. Industrial Applications

1. Motors and Generators

In industrial environments, resistor starting is commonly used for large motors and generators, where controlling inrush current is critical for system stability.

2. Pumps and Compressors

Pumps and compressors often require high starting torque, making resistor starting an ideal choice to ensure smooth operation without damaging the equipment.

B. Commercial Applications

1. HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems frequently utilize resistor starting to manage the starting currents of large motors, ensuring efficient operation.

2. Elevators and Escalators

In elevators and escalators, resistor starting helps to provide a smooth and controlled start, enhancing passenger comfort and safety.

C. Residential Applications

1. Home Appliances

Some home appliances, such as washing machines and refrigerators, may use resistor starting to manage motor operation effectively.

2. Small-Scale Machinery

Small-scale machinery, including woodworking tools and garden equipment, can benefit from resistor starting to ensure reliable performance.

V. Advantages of Resistor Starting

Resistor starting offers several advantages that make it a popular choice in various applications.

A. Reduced Inrush Current

By limiting the initial current flow, resistor starting helps to prevent voltage drops and protects both the motor and the electrical supply system.

B. Improved Motor Life and Performance

Controlling the starting current reduces mechanical stress on the motor, leading to improved longevity and performance.

C. Enhanced Control Over Starting Torque

Resistor starting allows for better control over the starting torque, making it suitable for applications requiring high torque at startup.

D. Cost-Effectiveness in Certain Applications

For many applications, resistor starting is a cost-effective solution compared to more complex starting methods.

VI. Challenges and Limitations of Resistor Starting

Despite its advantages, resistor starting also presents several challenges and limitations.

A. Heat Generation and Dissipation

The resistors used in this method generate heat, which must be managed to prevent damage to the components and surrounding equipment.

B. Complexity in Design and Implementation

Some models of resistor starting can be complex to design and implement, requiring careful planning and engineering.

C. Maintenance Requirements

Regular maintenance is necessary to ensure the resistors and associated components function correctly and safely.

D. Limited Use Cases

While effective in many applications, resistor starting may not be suitable for all motor types or operational conditions.

VII. Future Trends in Resistor Starting Technology

As technology advances, several trends are emerging in the field of resistor starting.

A. Integration with Smart Technologies

The integration of smart technologies and IoT devices is expected to enhance the control and monitoring of resistor starting systems, improving efficiency and performance.

B. Advances in Materials and Components

New materials and components are being developed to improve the efficiency and heat management of resistor starting systems.

C. Potential for Energy Efficiency Improvements

As energy efficiency becomes increasingly important, resistor starting technology may evolve to provide even greater energy savings in various applications.

VIII. Conclusion

In summary, resistor starting is a vital technique in electrical engineering, offering a reliable method for controlling motor startup. With various models available, each with its unique advantages and limitations, understanding these options is essential for selecting the right method for specific applications. As technology continues to advance, the role of resistor starting in modern electrical systems will likely evolve, further enhancing its importance in the industry.

IX. References

A. Suggested Reading

- "Electric Motor Control" by Frank D. Petruzella

- "Electrical Engineering: Principles and Applications" by Allan R. Hambley

B. Relevant Industry Standards and Guidelines

- National Electrical Manufacturers Association (NEMA) Standards

- Institute of Electrical and Electronics Engineers (IEEE) Standards

C. Academic Journals and Articles on Resistor Starting

- IEEE Transactions on Industry Applications

- Journal of Electrical Engineering & Technology

By understanding the popular models of resistor starting, engineers and technicians can make informed decisions that enhance the performance and reliability of electrical systems.