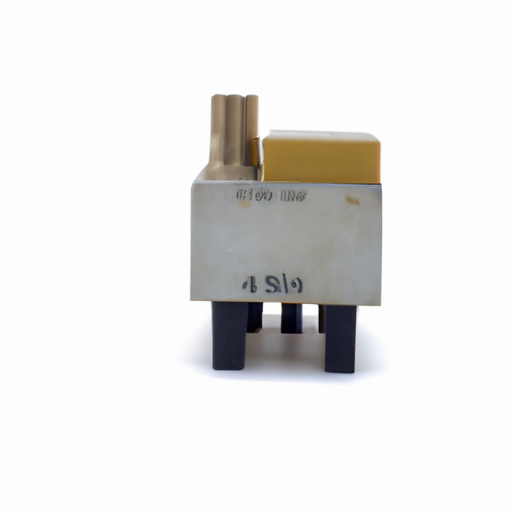

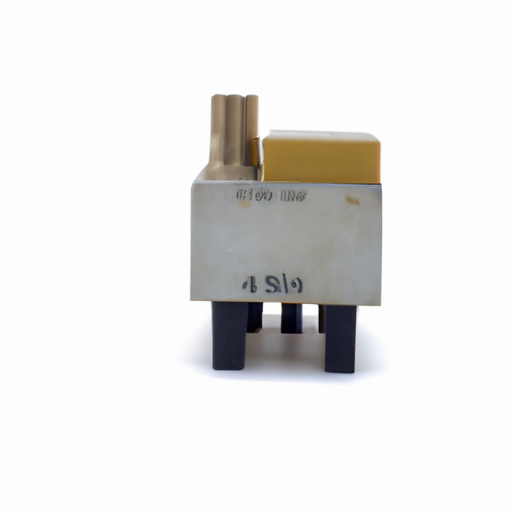

Overview of Mechanical Thermostats and the MM74HC221AN

While the MM74HC221AN is a dual retriggerable monostable multivibrator primarily used in timing applications, it can be integrated into temperature control systems, enhancing the functionality of mechanical thermostats. Mechanical thermostats themselves are essential components in various applications, leveraging simple yet effective technologies to maintain temperature control. Below, we explore the core functional technologies of mechanical thermostats and highlight application development cases that demonstrate their effectiveness.

Core Functional Technologies of Mechanical Thermostats

| 1. Bimetallic Strips | |

| 2. Mercury Switches | |

| 3. Mechanical Linkages | |

| 4. Calibration and Adjustment | |

| 1. HVAC Systems | |

| 2. Refrigeration Units | |

| 3. Water Heaters | |

| 4. Industrial Equipment | |

| 5. Home Appliances | |

Application Development Cases

Integration with MM74HC221AN

The MM74HC221AN can be integrated into systems utilizing mechanical thermostats to enhance their functionality. For example, it can be used to create a timed delay in HVAC systems, allowing for smoother transitions between heating and cooling modes. This integration can improve energy efficiency and user comfort by preventing rapid cycling of the heating or cooling systems.

Conclusion

Mechanical thermostats, utilizing technologies such as bimetallic strips and mechanical linkages, are vital in various applications, from HVAC systems to industrial equipment. Their reliability, simplicity, and cost-effectiveness make them a preferred choice in many scenarios. As technology advances, the integration of mechanical systems with digital components like the MM74HC221AN can further enhance their functionality, leading to smarter and more efficient temperature control solutions.

Overview of Mechanical Thermostats and the MM74HC221AN

While the MM74HC221AN is a dual retriggerable monostable multivibrator primarily used in timing applications, it can be integrated into temperature control systems, enhancing the functionality of mechanical thermostats. Mechanical thermostats themselves are essential components in various applications, leveraging simple yet effective technologies to maintain temperature control. Below, we explore the core functional technologies of mechanical thermostats and highlight application development cases that demonstrate their effectiveness.

Core Functional Technologies of Mechanical Thermostats

| 1. Bimetallic Strips | |

| 2. Mercury Switches | |

| 3. Mechanical Linkages | |

| 4. Calibration and Adjustment | |

| 1. HVAC Systems | |

| 2. Refrigeration Units | |

| 3. Water Heaters | |

| 4. Industrial Equipment | |

| 5. Home Appliances | |

Application Development Cases

Integration with MM74HC221AN

The MM74HC221AN can be integrated into systems utilizing mechanical thermostats to enhance their functionality. For example, it can be used to create a timed delay in HVAC systems, allowing for smoother transitions between heating and cooling modes. This integration can improve energy efficiency and user comfort by preventing rapid cycling of the heating or cooling systems.

Conclusion

Mechanical thermostats, utilizing technologies such as bimetallic strips and mechanical linkages, are vital in various applications, from HVAC systems to industrial equipment. Their reliability, simplicity, and cost-effectiveness make them a preferred choice in many scenarios. As technology advances, the integration of mechanical systems with digital components like the MM74HC221AN can further enhance their functionality, leading to smarter and more efficient temperature control solutions.